Anahita GmbH

Booth number: HALL 8 - 809A

anahita-gmbh.de/

About us

Our company specializes in the design and development of high-frequency pipe welding and annealing machines. We leverage the latest semiconductor technologies, including MOSFET, IGBT, and SiC FET, to deliver cutting-edge solutions.

In addition to welding systems, we offer a comprehensive range of machinery and equipment for the entire ERW pipe production process, including:

Material handling: Uncoilers, strip-head cutters, and welders

Storage & Accumulation: Horizontal and vertical strip accumulators

Forming & Welding: HF pipe welders and forming machines

Cooling & Sizing: Cooling systems and sizing units

Cutting & Finishing: Automatic cold flying saws, run-in and run-out tables

We are proud to provide businesses across Europe not only with high-quality machinery but also with end-to-end support, including installation, automation integration, and ongoing maintenance. Our goal is to ensure seamless operations and long-term success for our customers.

Address

Wellensiek 111

33619 Bielefeld

Germany

E-mail: info@anahita-gmbh.de

Phone: +49 521 9890170

Internet: anahita-gmbh.de/

Contact person:

Amir Malek

Mechanical Engineer

E-mail: amir.malek@anahita-gmbh.de

Hossein Malek

Technical Director

E-mail: h.malek@anahita-gmbh.de

Electrical Engineer Sina Malek

Electrical Engineer

E-mail: s.malek@anahita-gmbh.de

Products & Services

High-frequency pipe welders (60–1200 kW)

Automatic cold saws for steel pipes (Ø 5–165 mm, wall thickness 0.3–6.0 mm, cutting speed 60–120 m/min)

Steel pipe mill lines (for round and square profiles)

Induction annealing systems (100–800 kW)

Mechanical and magnetic pipe stacking machines (for round and square pipes)

Induction Annealing Machine for Stainless Steel Pipe

Induction annealing equipment is a special equipment used to heat stainless steel online to 1100 ℃ with any Shielding gases.

We offer cooling system to quickly cool it to below 100 ℃ under the protection of hydrogen.

Tube Mill Production Line

The machine can produce pipes in various shapes and sizes, depending on the requirements. It can produce round, square or rectangular tubes with different thicknesses, lengths and diameters. It can also process different types of steel materials, including carbon steel, stainless steel and aluminium. One of the main advantages of the steel tube machine is its speed and efficiency. The machine can produce pipes in large quantities within a short period of time, which shortens your lead time and reduces manufacturing costs. In addition, the steel tube machine can produce tubes with consistent quality and precise dimensions, eliminating the need for rework and reducing material waste. The machine is easy to operate and can be customised to individual requirements. It is equipped with user-friendly interfaces that make it easy for the operator to monitor and control the production process.

Pipe Stacking Machine

The pipe stacking machine include the following process: pipe loading, pipe laying & counting, up and down lifting, pipe ends alignment, bundle carrying out . The Tube Stacking Machine can stack pipe and tube automatically, max package weight can reach to 2tons. It includes an automatic electronic control. This enables reasonable and higher automation, can run continuously 24hours, and is able to meet the speed 60m/min for the tube mill line .

It is suitable for square and rectangular tubes.

Automatic Cold Saw for stainless Steel Pipe

Auto and Manual control

Length tolerance: ±0.5mm

Excellent cutting edge

No Burrs

Friendly HMI

Stable and Reliable

Quiet and High safety

Large LCD touch screen

Energy Efficient

Siemens servo system

We provide machines with power from 60 kW to 1200 kW, which can weld pipes with diameter from 8 to 398 mm and thickness from 0.2 to 15 mm.

Energy saving of 15-25% compared to traditional solid state welders

Less Covered Area

Easy installation

Less installation costs

High Welding Quality

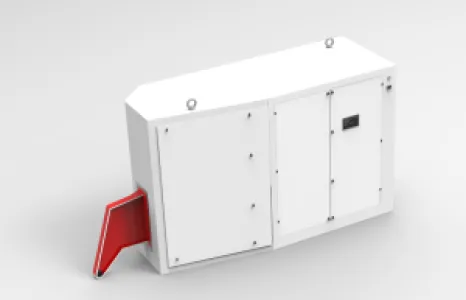

3 Generation High Efficiency Welder (SIC Series)

Compact design (3 Modules)

60 kW to 1400 kW

Thickness : 0,2 - 16 mm

Diameter : 8 - 420 mm

improved weld quality , production speeds

harmonic interference with a power factor of 0.96 or higher compliant with energy standards

Technology from the year 2019

Technical Principal : IGBT & SIC

Low Conduction Loss : Enhanced energy efficiency

20% lower capacitance compared to MOSFETs reduced power consumption

Use of SIC diodes Efficiency up to 90%

Higher voltage rating

Higher working temperature

Larger continuous current

Fast erswitching speed, lower switching loss

2.5 Generation High Frequency Welder (MOSFET Series)

Compact Design (3 Modules)

Thickness : 0,2 - 15 mm / 8 to 398 mm Diameter

Technology from the year 2014

Technical Principal : IGBT & MOSFET

Good for Seamless and ERW pipes

Ideal for ; steel, aluminum, brass, and copper.

60 kW to 1200 kW available

Up to 120 Meters per Minute (ideal solution for high-volume)

Low Noise and Energy Saving capability

2 Generation High Frequency Welder (SCR Series)

Solid State High Frequency Welder (5 Modules)

50 kW - 1200 kW / 0,2 - 15 mm Thickness

8 - 398 mm Diameter

Technical Principal : SCR & MOSFET

Cost effective

Advanced thyristor and MOS

Long lasting build

No need for output transformator